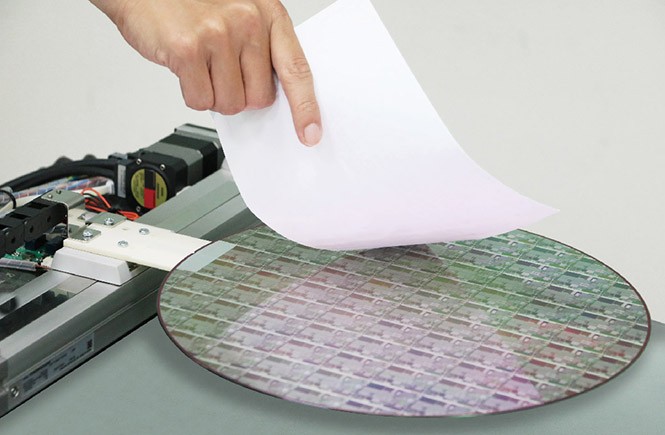

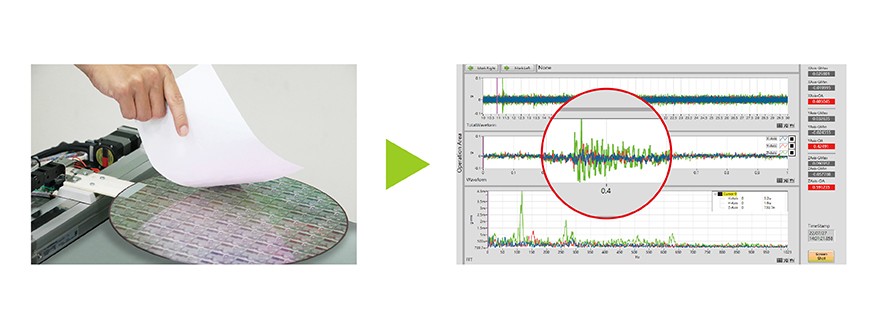

Since the semiconductor manufacturing process is highly automated, it depends on the robotic arm to complete the moving operations once the wafer is inserted into the machinery. In order to improve the stability of the robotic arm and achieve real-time detection of wafer damage, collision interference and other sporadic abnormalities, it is customarily necessary to install sensors on the equipment or robotic arm for long-term monitoring in order to determine the current production status or anomaly reports.

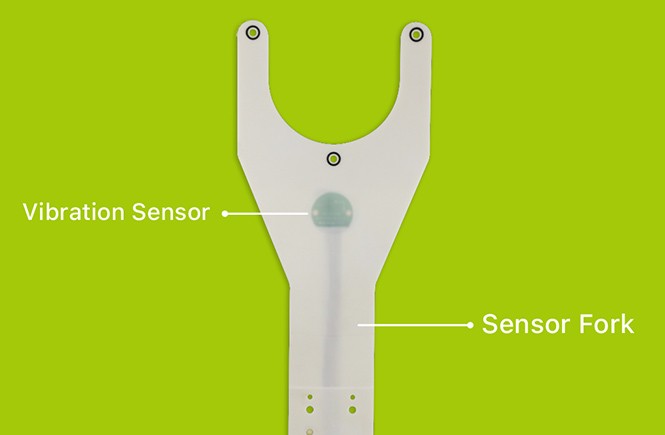

Microprogram exclusively designed Smart Robot Blade/Fork with our partners. The sensor is integrated into the blade/fork with a unique and patented design, which is more sensitive than an external sensor and can detect the motion of a robot or wafer. The blade's exterior size is unaffected, the sensors are concealed and simultaneous online measurement is supported to achieve real-time equipment abnormality monitoring. In addition, it offers a number of services, including data collection, data uploading, feature calculation and analysis software, learning algorithms to aid operators in accurately understanding vibration data, immediately identifying failure points and effectively enhancing the process yield and machine utilization.

Problems we solve

- Positional deviations or wiggles result in impact fracture

- Man-made or natural disasters and other forms of external interference

- The Robot's operation is unstable due to the combination of factors that result in its abnormal loading

Key advantages

- The sensors embedded in the blade with patented technology can detect more precise vibration data

- Vibration transmission is superior to external sensors on the market

- Support lengthy continuous measurement and On-Line measurements on the production line

- AI learning monitoring action pattern can be loaded

- The software is compatible with local storage and has analysis capabilities

- SECS/GEM format can be uploaded via repeater

Be our partners

- Semiconductor factory (front-end and back-end process portions, ATP)

- Semiconductor equipment manufacturer

- Original manufacturer or repairer of the robot

Scenarios

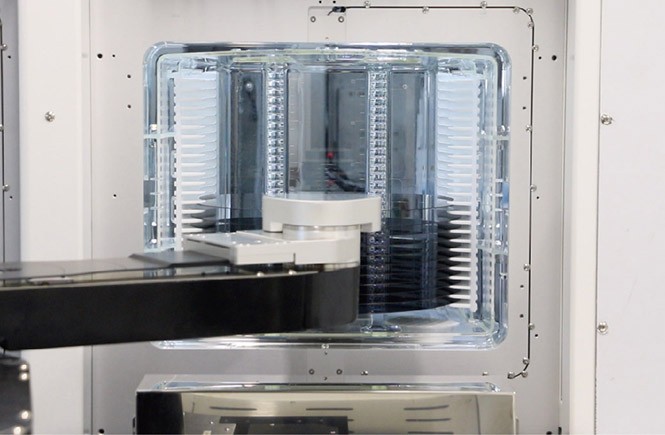

- Wafer handling robot (FI/Vacuum Robot)

- Equipments such as EFEM, sorter and inspection

Key features

Real-time online vibration monitoring

- Occasional anomalies are not overlooked

- Does not affect the exterior size of the blade

- The sensor is concealed and no pollution

Sensitivity gets better the closer to the wafer

- First to position the sensor directly beneath the wafer for more precise sensing

- Better sensitivity than typical external sensor

Custom embedding is possible for all types of blades

- Compatible with 8-inch or 12-inch wafer-handling blade

- Types of vacuum or negative pressure are both feasible

- Applicable to aluminum alloy or ceramic blades

Service Architecture