Smart Robot Blade/Fork

- The sensors embedded in the blade with patented technology can detect more precise vibration data

- Support lengthy continuous measurement and On-Line measurements on the production line

- Vibration transmission is superior to external sensors on the market

- Custom embedding is possible for all types of blades including vacuum/negative pressure, aluminum alloy or ceramic blades)

- Learning algorithms can be imported into microcontroller unit (MCU)

- Various modes of communication supported

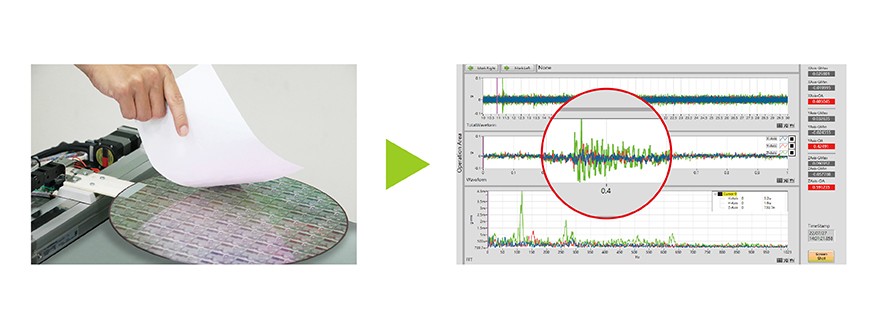

Since the semiconductor manufacturing process is highly automated, it depends on the robotic arm to complete the moving operations once the wafer is inserted into the machinery. In order to improve the stability of the robotic arm and achieve real-time detection of wafer damage, collision interference and other sporadic abnormalities, it is customarily necessary to install sensors on the equipment or robotic arm for long-term monitoring in order to determine the current production status or anomaly reports.

Microprogram exclusively designed Smart Robot Blade/Fork with our partners. The sensor is integrated into the blade/fork with a unique and patented design, which is more sensitive than an external sensor and can detect the motion of a robot or wafer. The blade's exterior size is unaffected, the sensors are concealed and simultaneous online measurement is supported to achieve real-time equipment abnormality monitoring. In addition, it offers a number of services, including data collection, data uploading, feature calculation and analysis software, learning algorithms to aid operators in accurately understanding vibration data, immediately identifying failure points and effectively enhancing the process yield and machine utilization.

Scenarios

- Wafer handling robot (FI/Vacuum Robot)

- Equipments such as EFEM, sorter and inspection

Specifications

| Items | Specifications |

|---|---|

| Robot Blade thickness | Under 3mm (Satisfy for 12/8/6 inches wafer) |

| Principle of Sensing | MEMS Accelerometer |

| Number of Axes | X,Y,Z – 3Axis G-Sensor |

| Channel | 3 (X,Y,Z) |

| Sensitivity |

0.061/0.122/0.244 mg/LSB (16384/8192/4096 LSB/g) |

| Operating Range | Range. ±2 / ±4 / ±8 G |

| Sampling Rate | 512Hz ~ 2kHz |

| Data Transfer | Bluetooth Low Energy |

| Sensor Operating Temperature | -20°C ~ +85°C |

| Support |

• Various material blade supported • MCU AI algorithm • SECS HSMS communication • On-Line / Off-Line analysis • DI/O interface |